The German based K. Chr. Steen GmbH & Co has been manufacturing deck equipment (e.g. anchor winches, capstans & various other anchoring solutions) since 1893. More than 130 years of development and manufacturing has established a reputation for top quality, super reliable deck gear with which many superyachts and navy vessels worldwide have been equipped.

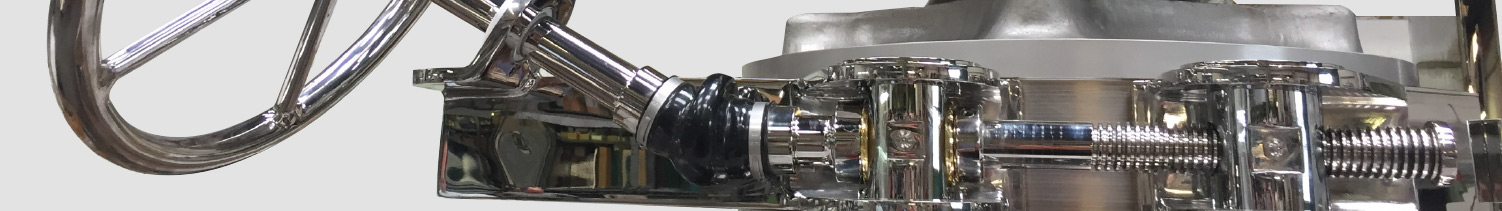

Workmanship as Trademark

Steen factory is home of specialists in mechanical engineering, constructions, welding, lathe operations, polishing and painting. Most of those have been working at the Steen factory for more than 20 years. Together, they represent the experienced workmanship for which Steen has become renowned. Looking forward to transfer experience, Steen continues educating young generation engineers.

Steen engineering shows parallels with the developments in the shipping and yachting industry. Steen has taken notice of the changing demands in the yacht building industry, resulting in the design of anchor capstans as an alternative to anchor winches in different, higher standards of finishing.

Except for the electronics and the casting of certain parts, everything is engineered and constructed in-house at Steen. “In our field, experience ensures quality. Our welders for instance are skilled engine fitters, able to weld different materials. For example if a bronze gearwheel needs a steel chain wheel or if a stainless steel casing is integrated in a steel superstructure.” Constructing cog wheels of a winch requires precision work. If a vessel is at anchor, the winch must be capable of holding the complete weight of the entire vessel.

Custom-made for clients’ demands

Among the long list of clients of Steen are merchant ships, navy vessels, special craft such as research, search & rescue vessels, barges, dredgers, marine construction sites and offshore units and many, many yachts in the range from 40 – 200 meters. For navy vessels and special craft, Steen has developed custom solutions. For example non-magnetic winches for minehunters, mine-sweeping winches, deep-sea rope anchor winches, deck cranes and gantry cranes. These developments and experience have been used in the development of top quality, state-of-the-art deck equipment for the largest mega-yachts.

In the early stage of the design process, both the shipyard and customer can draw on advice for optimal winch installation and find arrangements which fit into the classification society (GL, LRS, DNV and ABS) rules and regulations.

For various mega-yachts Steen designed and developed a custom/special solutions together with shipyards and designers to achieve optimal design and implementation that complement practicality, safety and design.

Over 1000 mega-yachts have been equipped with Steen deck machinery. Typical clients include Lürssen, ThyssenKrupp Marine Systems, Abeking & Rasmussen, Feadship/ Royal de Vries, Royal Van Lent, Amels, Hakvoort, Oceanco, Heesen, Kusch Yacht Bau, Fincantieri, Dubai Ports, Derecktor Shipyards and many many more.

Certified equipment

Building deck equipment to yacht standards not only requires the best quality of materials and finishes, but for safety and reliability. “We see each anchor winch as safety equipment on which captain, crew and passengers must be able to rely on. When for instance the yacht is anchored and strong winds yawes at anchor”, the reliability of the equipment is instrumental to all onboard.

Steen deck machinery is constructed in compliance with regulations of Germanischer Lloyd and Lloyds Register. Winches are furthermore capable of offering more pulling power than is strictly required.

The type and size of anchor winch is based on the size and quality of the selected type of chain determined by rules of classification society.

Investment for endurance

Steen winches are designed for a long lifetime. The steam engine on board the renovated ship ‘Skjelskoer” build in 1914 and the steam-driven crane winch in the Hamburg Museum of Labour are both still in operation.

Such custom made and high quality deck machinery are renowned for their reliability and endurance and thus a good return of investment.

Innovating for a changing market

Since Steen was founded in 1893, the company has not only designed and constructed deck machinery that last more than a lifetime, it continues improving its products to meet the demands of its market.

Not only in the design and the finish, but also in the technology of the winches. This means using modern and integrated hydraulics and electronics. To control the chain speed independent of the pulling power, Steen uses frequency regulators.

Steen can supply winches suitable for use in tidal waters. Pulling power and chain length of these winches are automatically regulated, taking into account currents and wind conditions.

Steen has developed and implemented a brake system for controlled self-acting lowering anchor systems. It also constructed a “mooring bollard”, which combines the characteristics of bollard and mooring capstan to optimize operation. In the range of yacht crane application Steen has also improved his capability.

“Boat Booms” for mega yachts of ca. 100 m or more has been developed for different design solutions. Complete built-in packages are offered (basic bow foundation including pre-installed anchor capstans). For sailing yachts and light displacement vessels or fast speed yachts, the company is working on special light weight winches made of titanium or other composites. Especially on sailing yachts and high-tech sailing yachts in particular, naval architects seek light-weight winches. Steen continues development to meet the demands of a changing market that is willing to invest in custom solutions, top-class workmanship and long-lasting quality also part of overall sustainability goals.

Since 1969, Technoship BV has been exclusive representative for K.Chr. Steen GmbH&Co KG. in The Netherlands and since 2021 in France as well.

K.Chr. Steen GmbH&Co KG, established in 1893, is a leading manufacturer of highest quality deck machinery. Steen deck machinery stands for safety, innovation, durability and immaculate workmanship. Steen is foremost supplier to superyacht, naval and other shipbuilders worldwide.

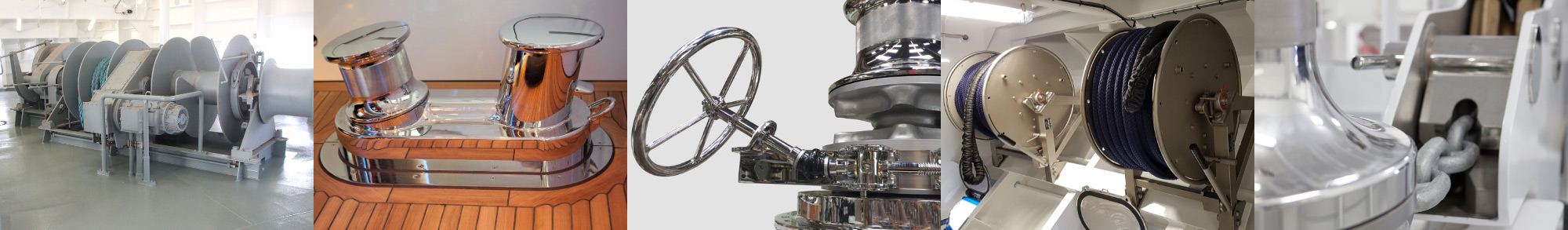

Steen designs and manufactures deck machinery, such as anchor windlasses, anchor capstans, mooring capstans, chain stoppers, chain compressors, chain guides, combined capstan-bollards and chain protection and special custom solutions for anchoring, mooring, towing and heaving. Its products are based on experience and made to last (some in use for over 50 years), and a true example of “Deutsche Gründlichkeit”.

Steen and it’s qualified and experienced in-house engineering team guarantee her deck equipment is not only robust and reliable, but user-friendly and simple to install as well.

Her safety features and quality control system to deliver fully tested and Class certified equipment make it the preferred choice for captains and crew.

Examples of vessels that rely on Steen deck equipment are megayachts (>700), navy vessels (>750), merchant vessels (>4000) and special craft such as polar research and oceanographic vessels, search and rescue vessels (>250).

Products

Since Steen was founded in 1893, the company has not only designed and constructed deck machinery that lasts more than a lifetime, it continues improving its products to meet the demands of its market.

Not only in the design and the finish, but also in the technology of the winches. This means using modern and integrated hydraulics and electronics. To control the chain speed independent of the pulling power, Steen uses frequency regulators.

Steen can supply winches suitable for use in tidal waters. Pulling power and chain length of these winches are automatically regulated, taking into account currents and wind conditions.

Steen has developed and implemented a brake system for controlled self-acting lowering anchor systems. It also constructed a “mooring bollard”, which combines the characteristics of bollard and mooring capstan to optimise operation. In the range of yacht crane application Steen has also improved his capability.

Anchoring Equipment

for 12.5 mm to 80 mm stud-link chain

- Windlasses

- Combined Windlass/Mooring Winches

- Anchor Capstans

- Anchor Sliding Devices

- Hand-operated Windlasses

- Chain Stoppers

- Chain Compressors

- Chain Guides

- Chain Protection

- Auto-Tensioning systems

- Devil’s Claws

Cargo-Handling Equipment

capacity: 0.5 to > 400kN

- Cargo Winches

- Heavy-Cargo Winches

- Topping Winches

- Slewing Winches

- Hand-operated Cargo Winches

Mooring Equipment

capacity: 0.5 to 400 kN

- Automatic Mooring Winches

- Non-automatic Mooring Winches

- Hand-operated Mooring Winches

- Capstans

- Combined Capstan-Bollards

- Rope Storage Reels

- Mooring Chocks, Clamps, Bitts, Rollers

- Fairleads

- Rope Stoppers

Towing Equipment

capacity: 10 to 500 kN

- Towing Winches

- Towing Bridle Winches

- Special Constructions

- Boat and Deck Cranes

- Friction Winches

- Rope Storage Winches

- Dredger Winches

- Slip Winches

- Auxiliary Winches

- Oceanographic Winches